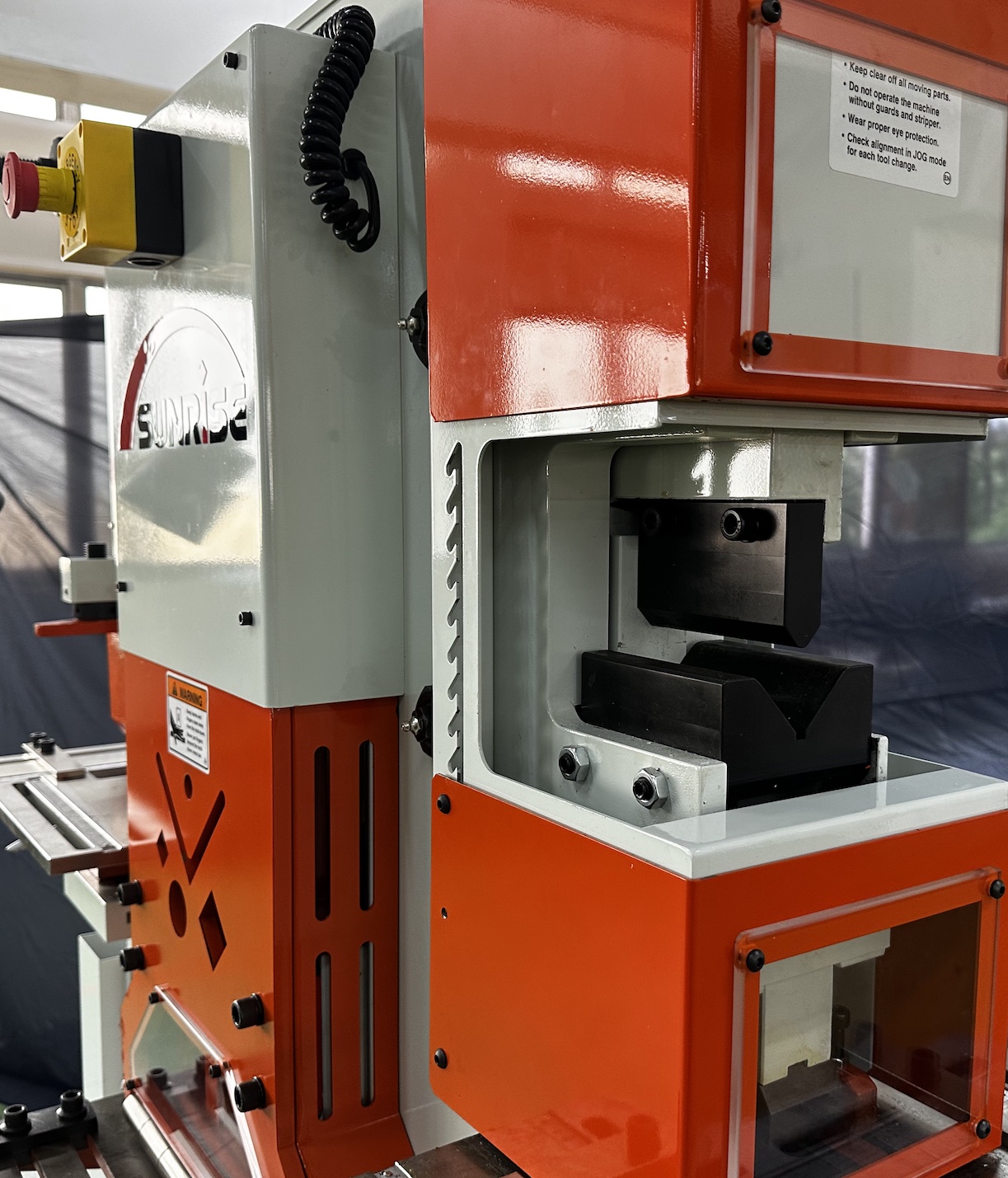

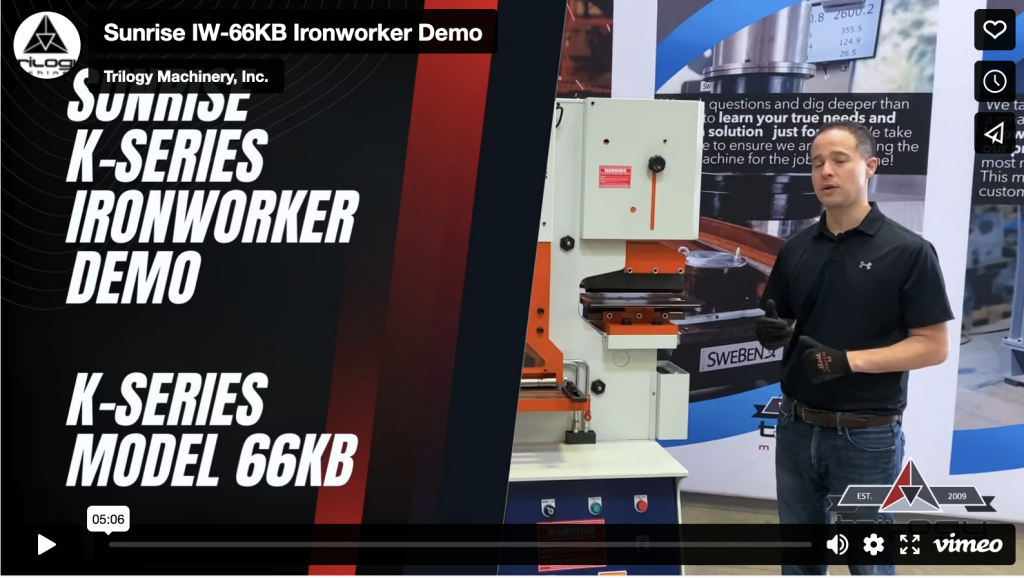

Introduced in 2004 the K-Series is a specially designed ironworker with vertical movement on all stations. The main slide moves up and down to provide optimum results for punching, shearing, notching, and bending without other moving parts.

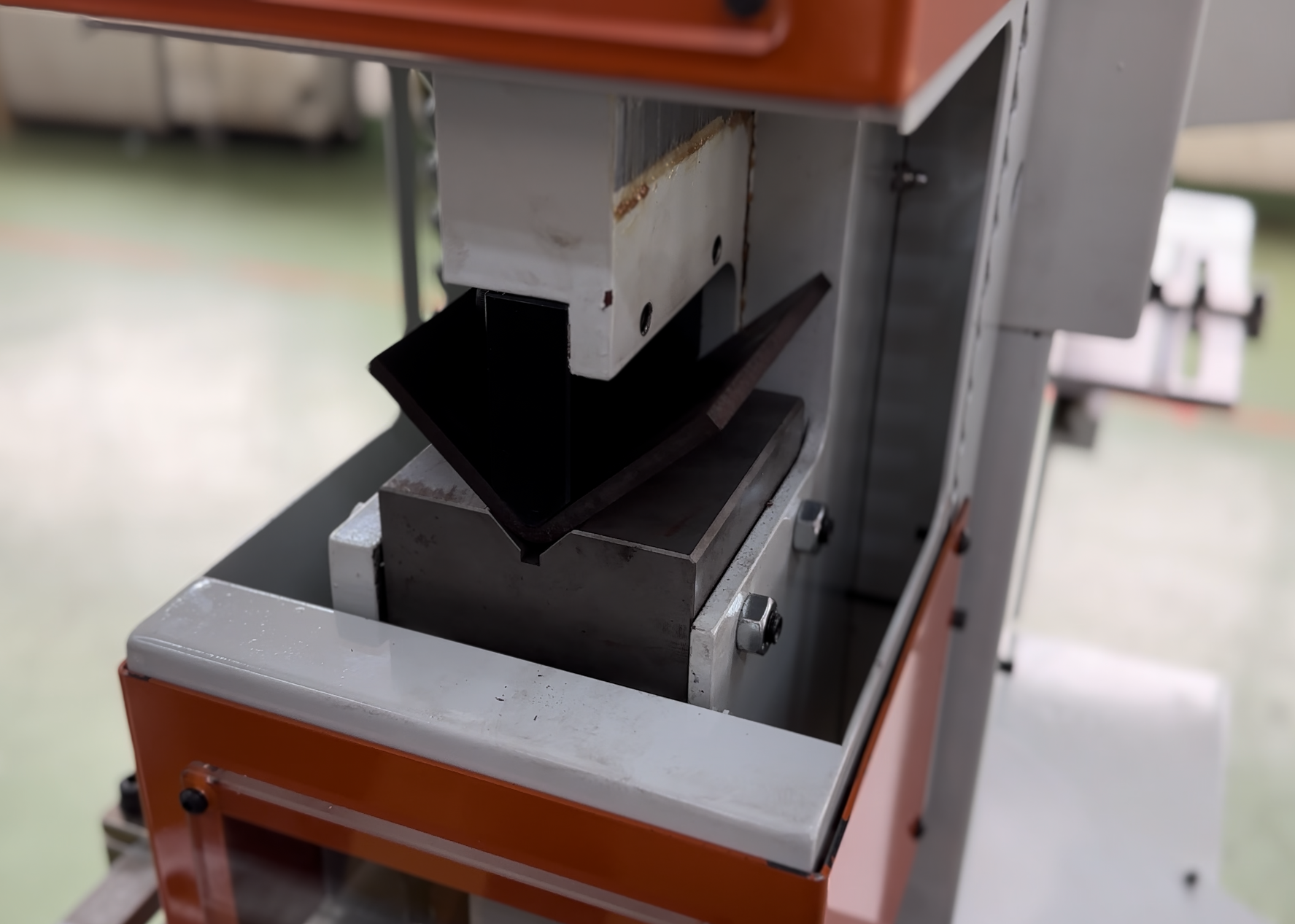

Both the punching and notching bases use “T-slots” which provide a solid base for securing the punch tooling, as well as a wide range of optional and custom-designed tooling, such as press brakes, vee-notchers, pipe notching, and more! The 66KB features and integrated 12″ Press Brake in place of the notcher, while the 66KBN features both an integrated 4″ press brake and a rectangular notcher!

Hydraulic hold-downs for shearing are standard on all models (except the IW-50K) which integrates into the standard electric back gauge, automating the shearing functions! The adjustable stroke, swing-away stripper, and high speed improve efficiency and allow greater operator control. The low-pressure mode for tooling alignment and blade changes provides the utmost safety for the operator, as well as multi-sided blades and adjustable blade gaps.

These models incorporate versatility, efficiency, accuracy, and ease of use at an excellent price. All K-Series models have a standard 3 Year Parts and 1 Year Labor Warranty!

Trilogy Machinery offers 100% factory-authorized service, support from their Maryland location, and a full OEM spare parts and accessories stock.