Sunrise ALS 1506D – Angle Line System with Auto Loader

$349,950.00 – 20 Foot system | $434,950.00 – 40 Foot System

Capacities

Sunrise ALS-1506D Capacities

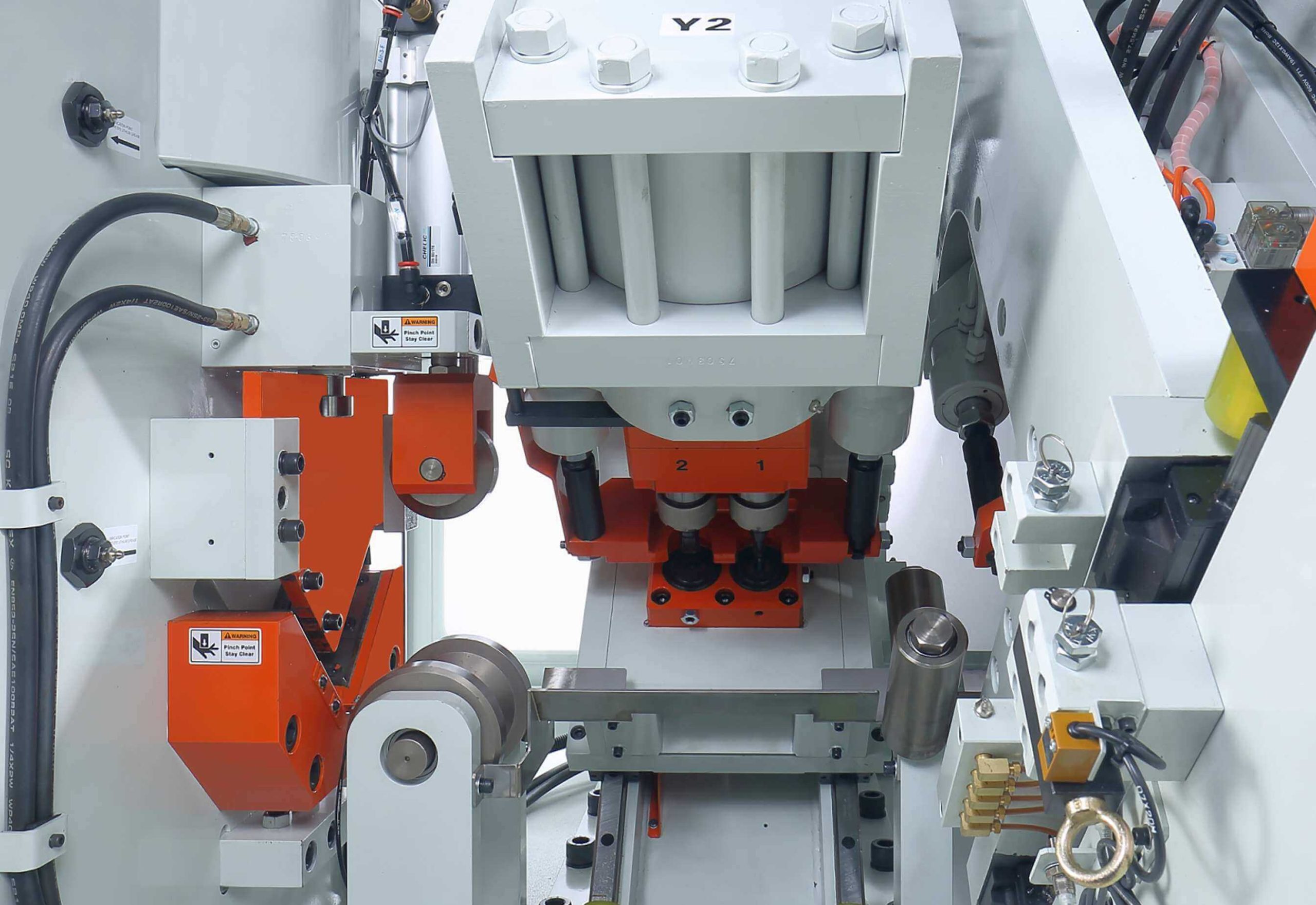

Punch: Dual 66-Ton Cylinders – Each with 2 independent punches.

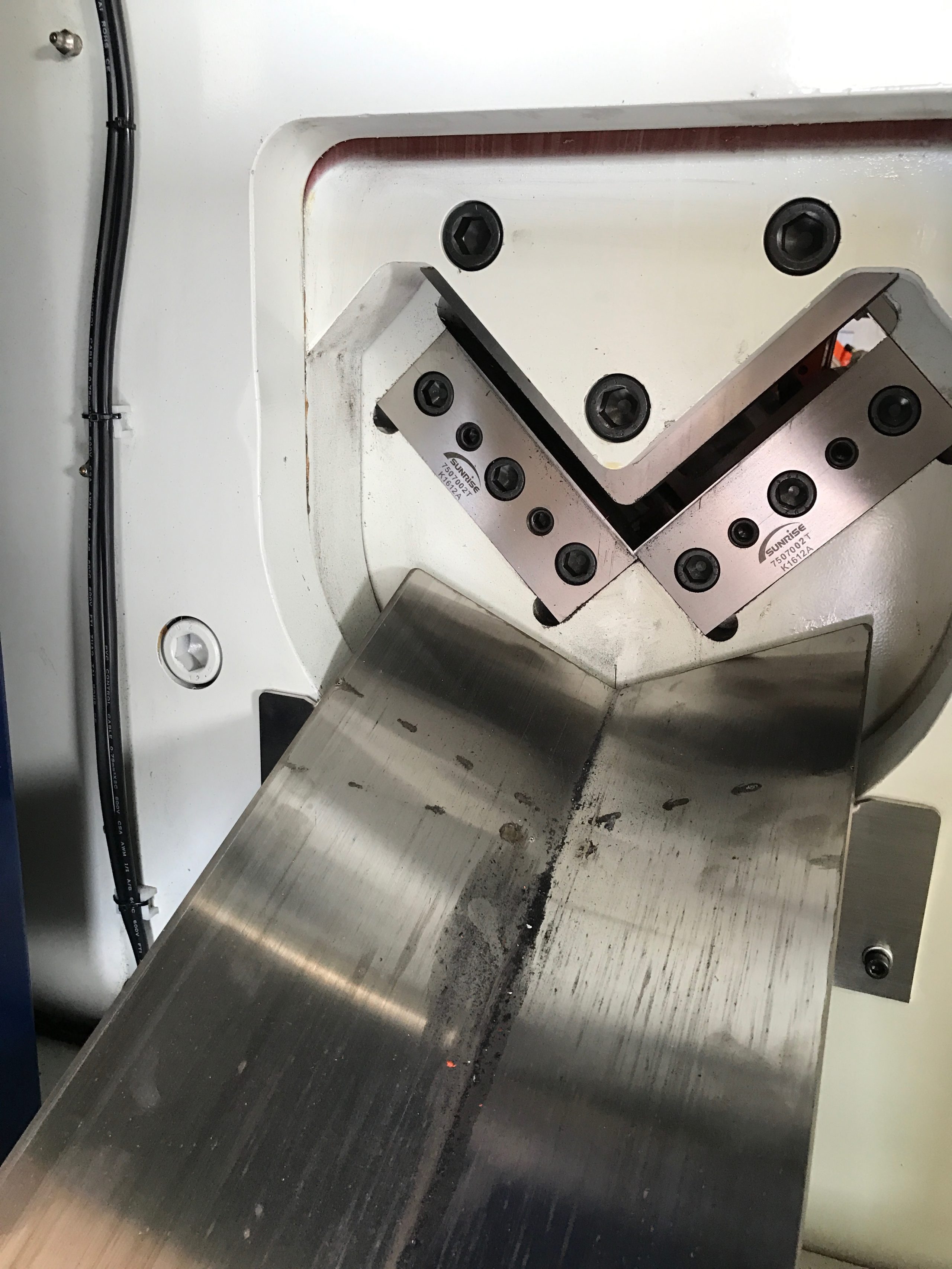

Angle Shear: 170 Tons – 2″ x 2″ x 1/4″ to 6″ x 6″ x 1/2″ – Optional tooling for 1-3″ and uneven leg angle.

Flat Bar Shear: 170 Tons – 2″ x 1/4″ to 6″ x 1/2″

HP: Multiple motors, valves and pumps to allow variable pressure on all stations.

Power Requirements: 3 Phase | 220 – 100 Amp | 480 – 60 Amp

Product Features

- Fully Automatic Angle Processing System with Auto-Loader capable of automatically loading and processing up to 8 sticks at a time.

- Dual 66-Ton Punches – Each with Hydraulic Punch Stripper and dual punches, each up to 1.5″ capacity, independently controlled

- Hydraulic Shear Hold Down for both Angle and Flat Bar

- Multiple pneumatic hold-downs, laser measurement system, and pneumatic gripper

- 20′ in-feed standard, expandable to 50′

- 15″ Touch-Screen controller, offline software, DXF/NC1 Import

- Optional Dot-Peen Marking System</>

Sunrise Angle Processing Systems include the following:

- On-Site Installation and Training for 2-3 days

- 2 Year Parts and Labor Warranty or 2500 Working Hours

- Complete safety system including fully enclosed operation area with safety interlocks

- Multi-sided and reversible blades, including blade gap adjustment, and no slug loss

- 6″ minimum scrap on each run, or optionally use the last piece, programmable trim cut

- Nesting, group nesting, and more.

- Complete tool kit with Manual, CAD Parts Drawings, Electrical and Hydraulic Schematics printed and loaded on a USB

SUNRISE offers one of the widest ranges of CNC options today, including semi and fully-automatic punches, automatic shearing, and new complete processing systems.

Description

The Sunrise Angle Line System – ALS – is a versatile and fully automated angle line processing system that efficiently processes angles and flat bars up to 6″ x 6 x 1/2″. It offers punching, shearing, and dot-peen marking capabilities, enhancing accuracy and productivity in metal fabrication applications.

Operation: The operator loads the angle onto the all-steel in-feed rollers; the system engages and pneumatically clamps the material, measures the length, and then processes the material by automatically punching both legs of the angle and shearing (without a slug) to length utilizing the industrial strength rack and pinion drive system. When the bar is complete, the system will automatically retract, drop the 6″ scrap, and move to the load position to repeat the process.

SUNRISE ironworkers and sytems offer the lowest cost of ownership among leading brands due to the integrated spin-on return line filter, bronze bushings and gibings, multi-sided blades and the highest quality components as well a standard two year parts warranty.

Accessories

Sunrise Angle Lines can feature Dot-Peen marking systems and Auto-Loading Systems. Check out the Sunrise Angle Processing System Page!