Sunrise: Punch Better.

Power. Versatility. Precision.

Sunrise Product Lines

K Series

K-Series Ironworker | 50-66 Tons

The K-Series is a special designed ironworker with vertical movement on all stations. The entire main slide moves in an up and down motion to provide optimum results for punching, shearing, notching and bending.

PM Series

Single End Punch Ironworker – 40-220 Tons

The Single-End Punching Machines from Sunrise range in capacity from 40 to 220 tons. Special designed patented hydraulic cylinders enable the machine to retract faster, also making the cylinders slimmer.

S/SD Series

Dual Cylinder Ironworkers | 66-185 Tons

The cornerstone of the Sunrise brand. Dual-Cylinder/Dual-Operator design and powerful capabilities, S/D series ironworkers enhance productivity and precision in metal fabrication operations. Available in 66-185 Tons | 5″-8″ Angle | 14″ – 30″ Flat Bar and more!

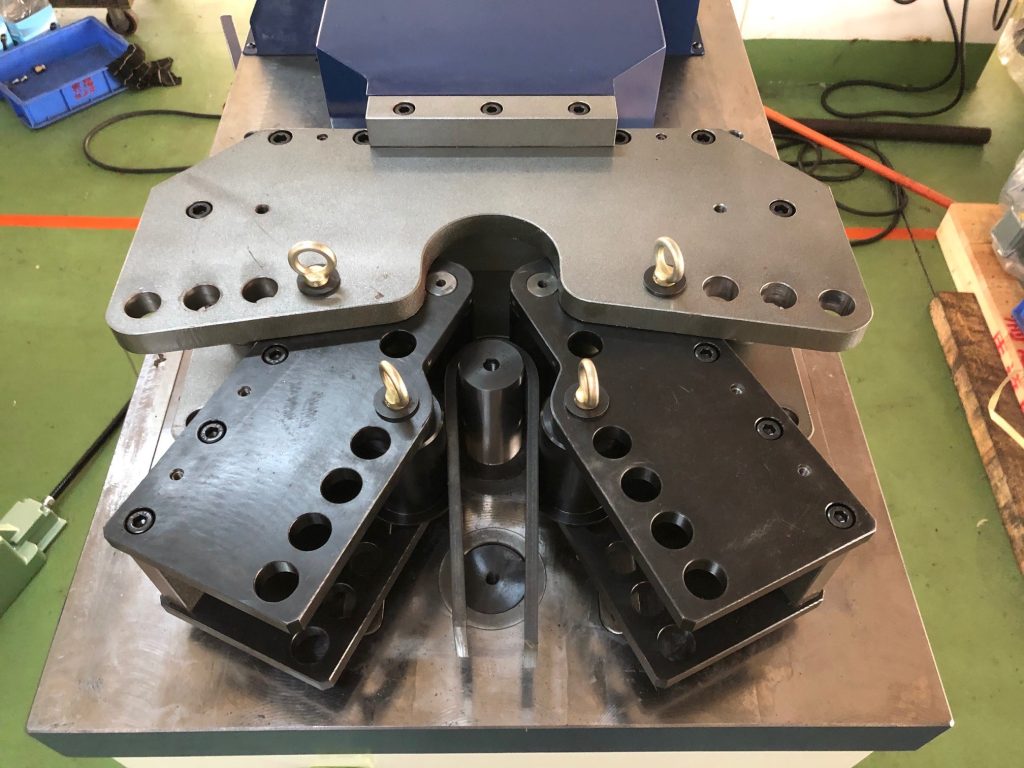

Horizontal Bending Machine (HBM)

Horizontal Bending Machine | 45 and 82 Tons

The Sunrise HBM horizontal bending machines, offer a wide range of tooling for different bending operations. Custom tooling and CNC back-gauges are also available.

Sunrise Semi-Automatic CNC Solutions

Sunrise Semi-CNC Solutions

Sunrise Semi-Automatic CNC Solutions include semi-CNC punching, automatic shearing, and linear punching systems.

Looking for SUNRISE parts?

We have them in stock! Contact us to learn more or place an order.