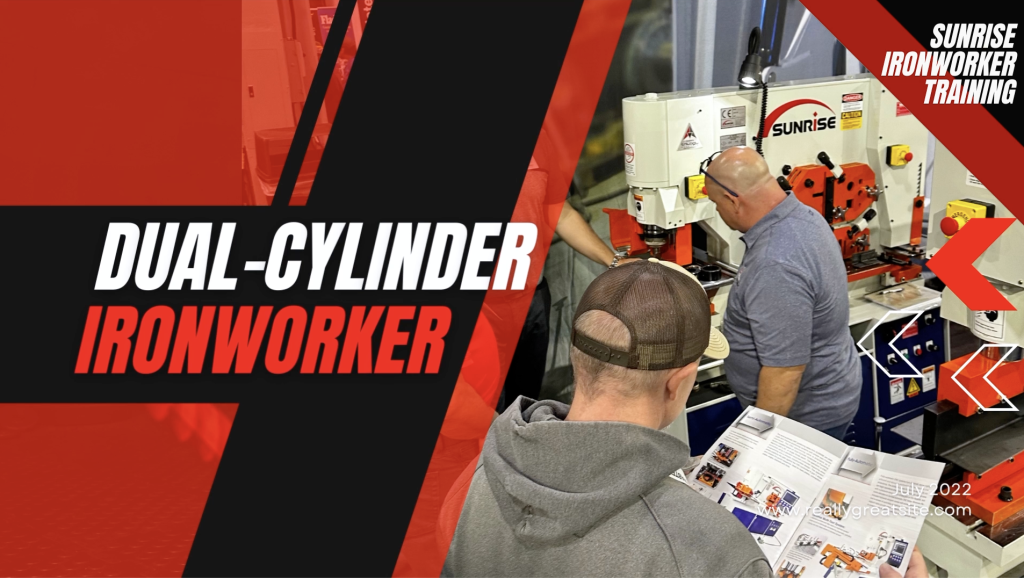

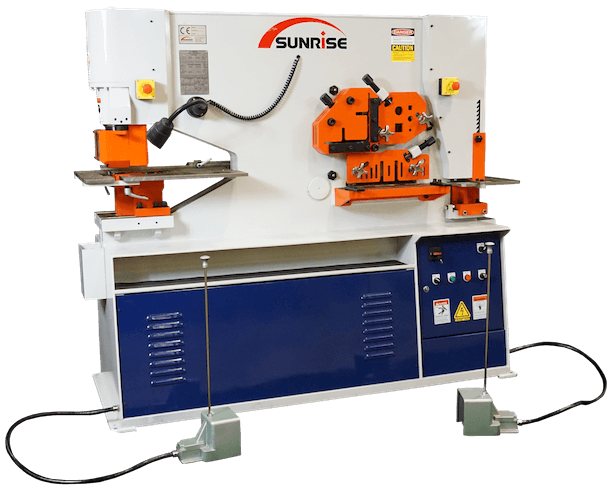

Get to know the S/SD Series

Standard Features

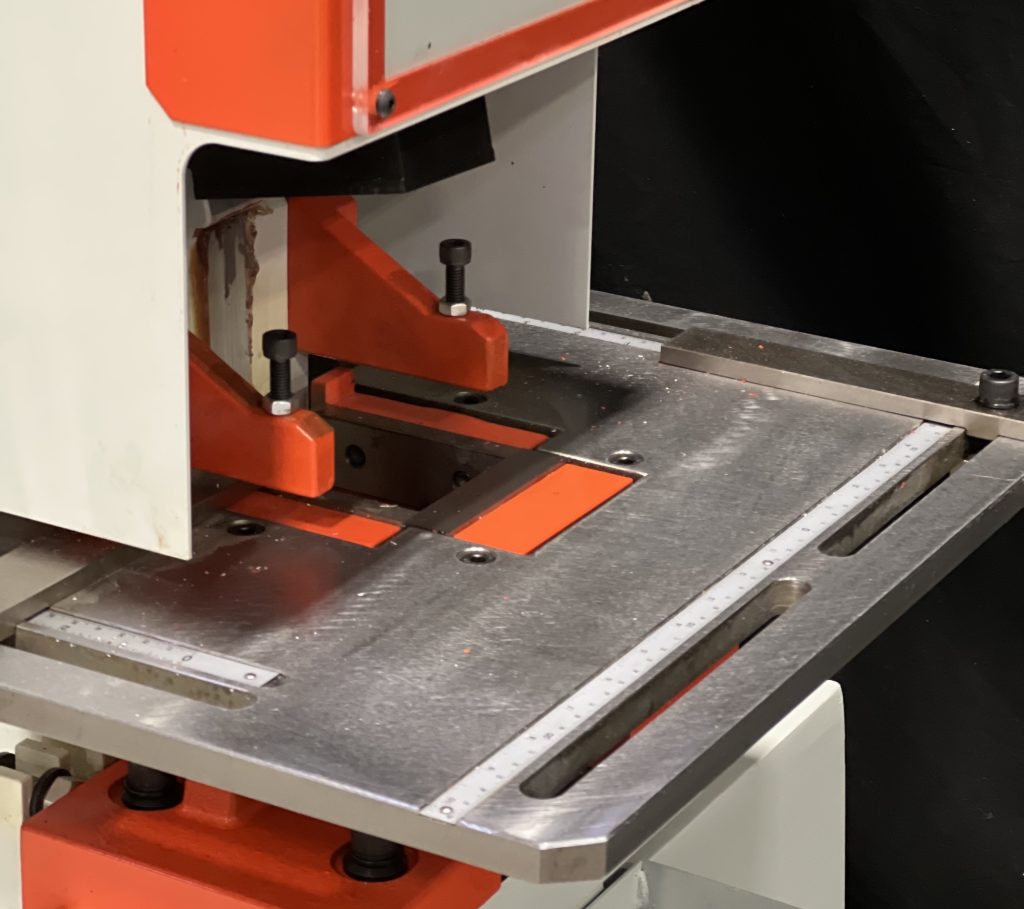

- 40″ Electric backstop for use with all shearing stations

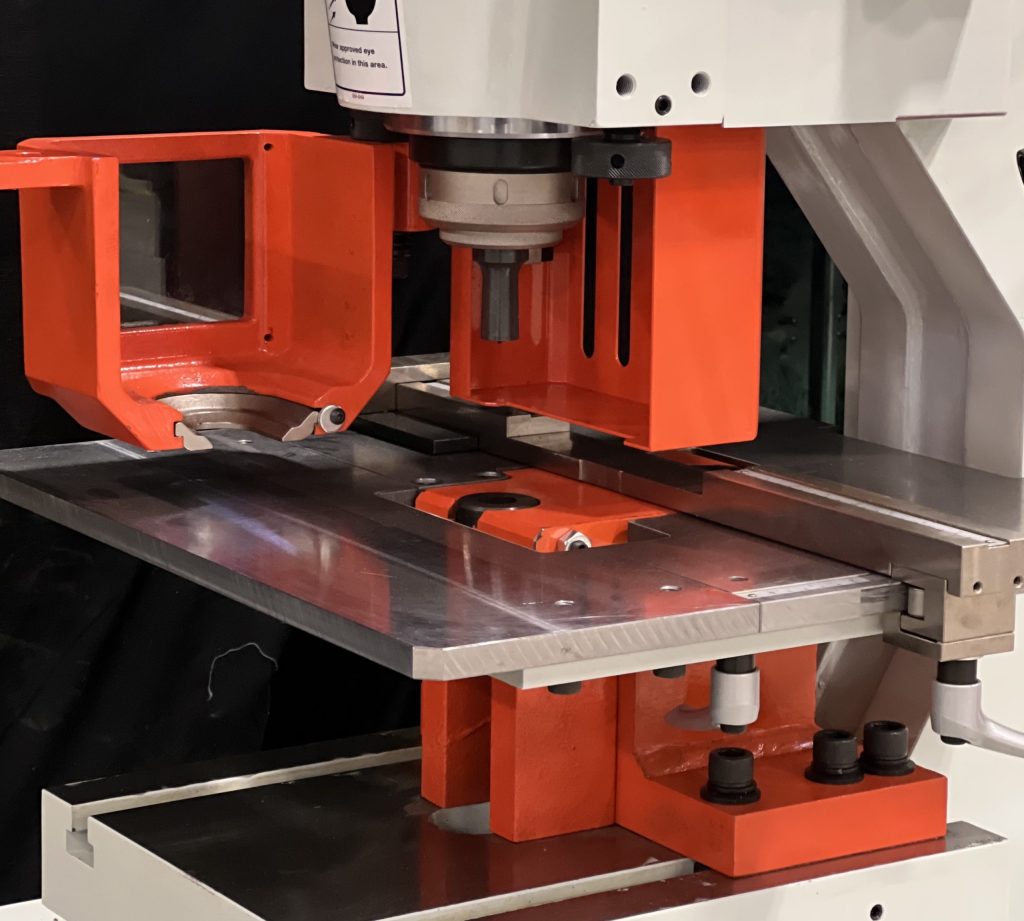

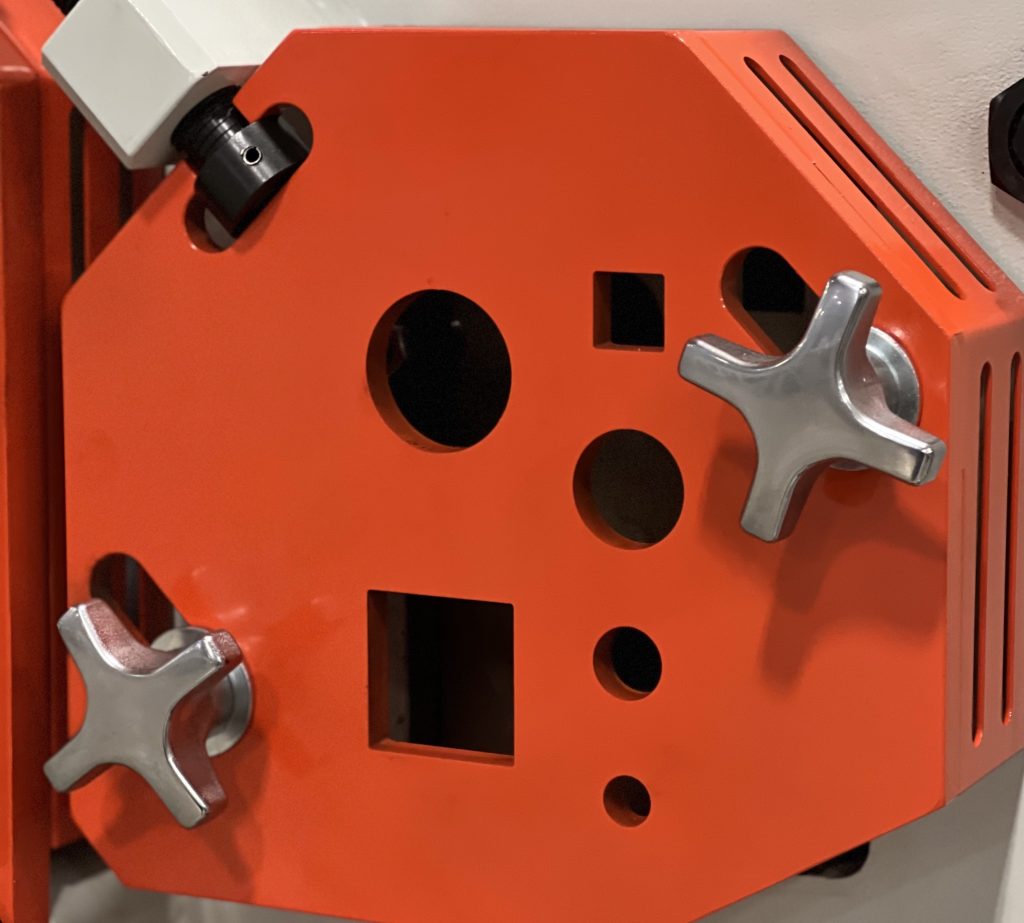

- Dual-opening die block for punching up to 2″ diameter holes, channel flanges, or angles, expandable to 8″

- Gauge tables for punching and notching stations

- Magnetic LED work light

- Set of 11 standard round punches and dies from 3/8″ to 1-1/2″

- 3 Year Parts, 1 Year Labor warranty

- Owner’s Manual, Tool Kit, Training video, Schematics, Parts Drawings

- Free lifetime technical support by phone or email

Optional Accessories and Features

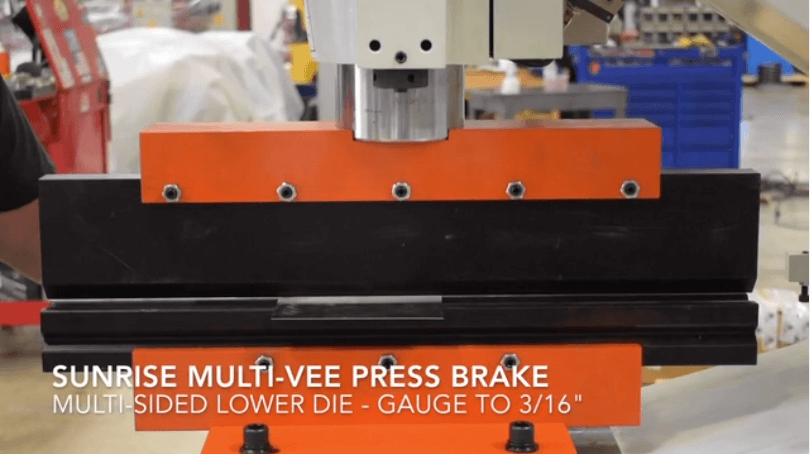

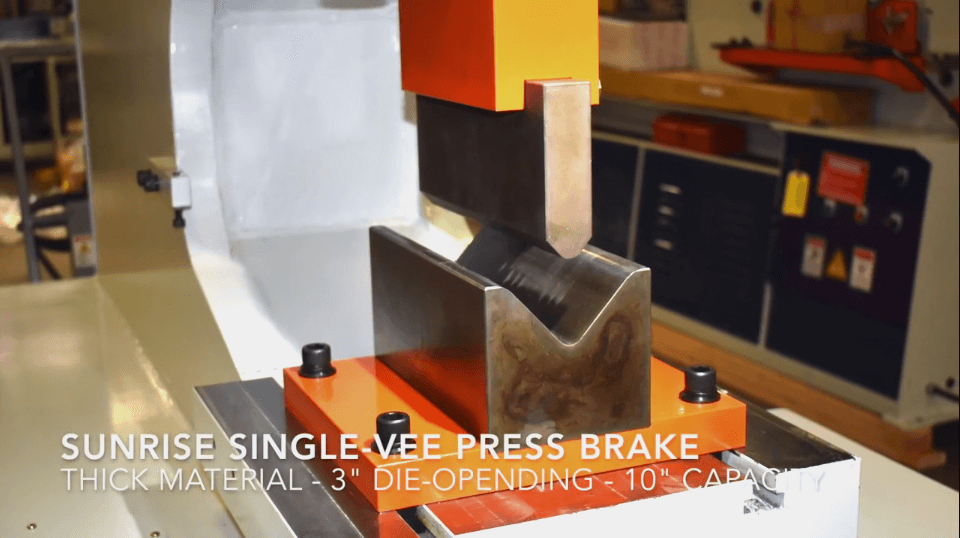

- Press brakes

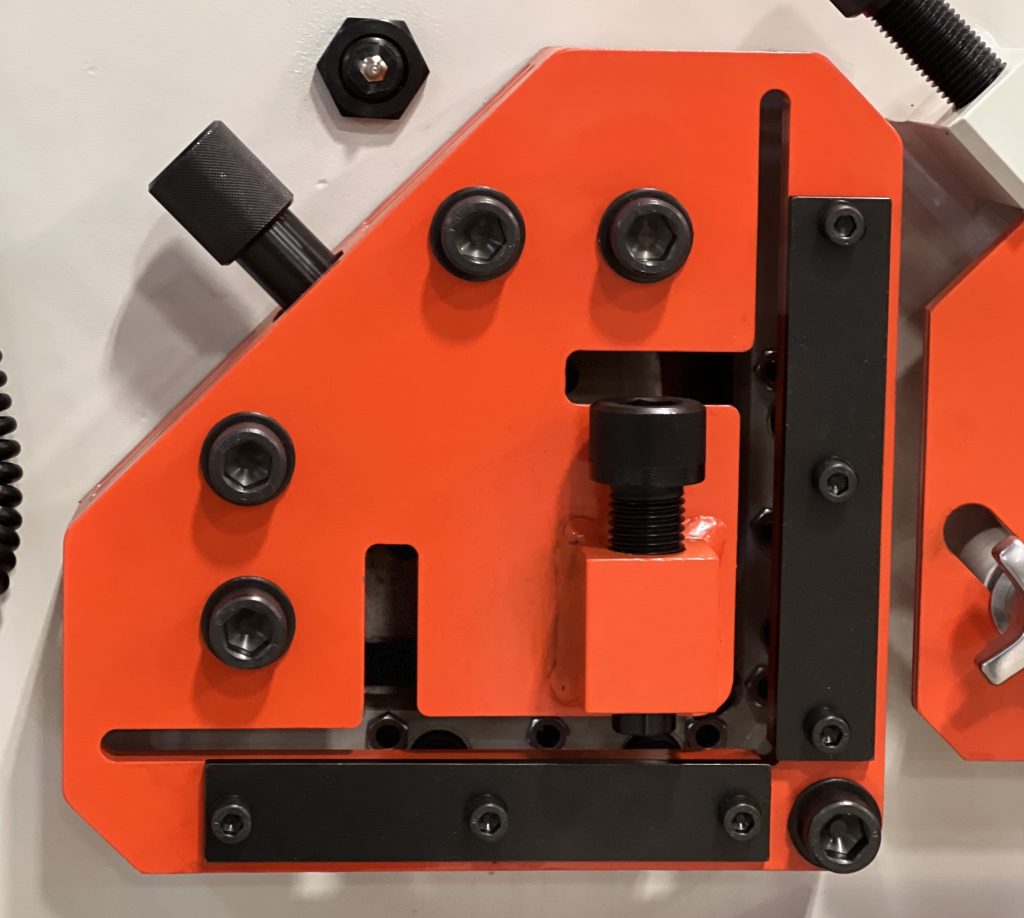

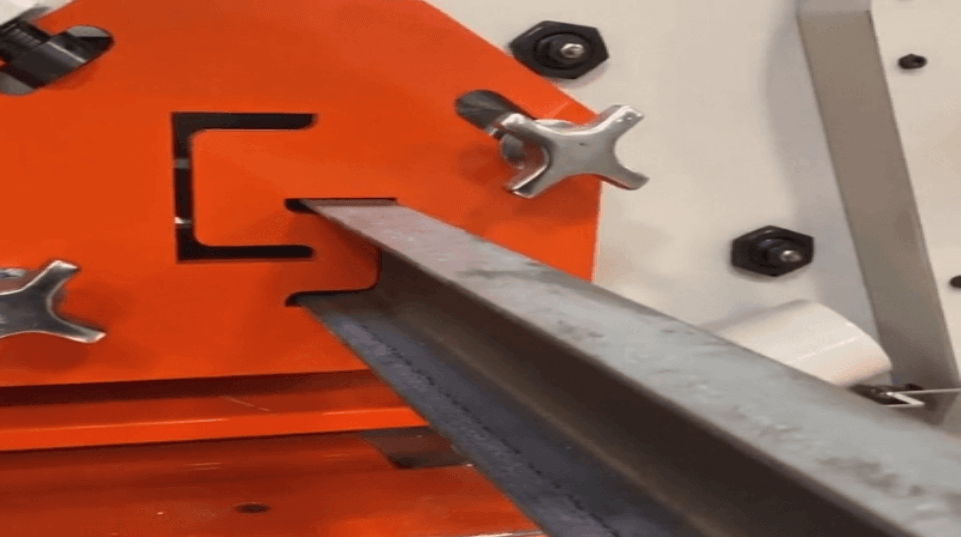

- Channel and structural blades

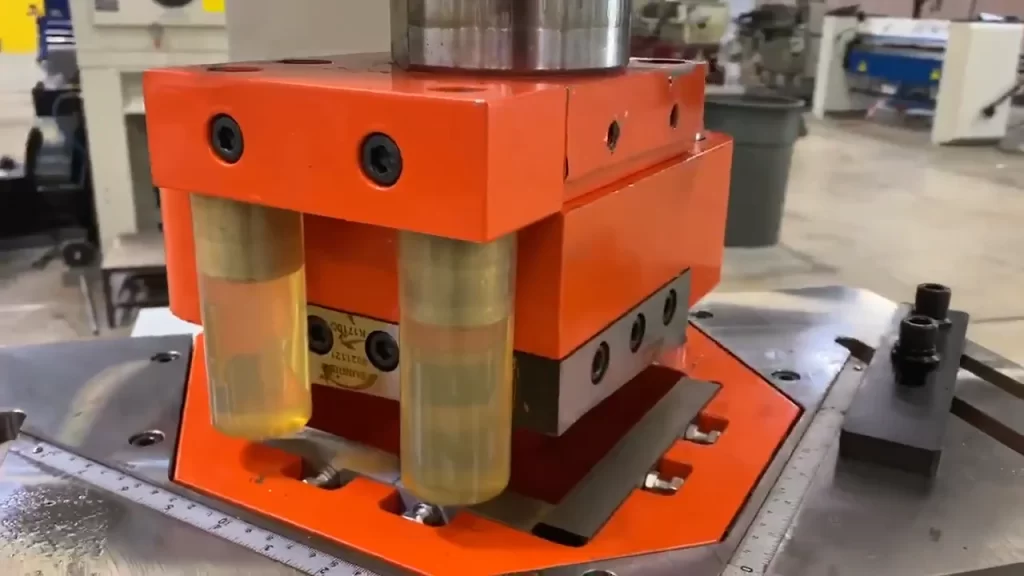

- Hydraulic stripper

- Hydraulic hold down for angle and/or plate shearing

- Triangular notchers

- Pipe notchers and more!

Sunrise CNC Options

Sunrise offers one of the widest ranges of CNC options, including semi and fully-automatic punches, automatic shearing, and angle, plate, and channel processing systems.

| Model | Capacity | Description | Price | Status | Info | |

|---|---|---|---|---|---|---|

| Sunrise IW-66S – Hydraulic Ironworker Capacity: 66 Tons | 5″ Angle | 14″ Plate |

66 Tons | 5″ Angle | 14″ Plate | New, Dual Cylinder, High-Speed, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$27,995.00 | In Stock! |

Get a Quote | |

|

Sunrise IW-66SD – Hydraulic Ironworker Capacity: 66 Tons | 5″ Angle | 14″ Plate |

66 Tons | 5″ Angle | 14″ Plate | New, Dual Cylinder, High-Speed, Deep-Throat, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$33,250.00 | In Stock! |

Get a Quote |

|

Sunrise IW-88S – Hydraulic Ironworker Capacity: 88 Tons | 6″ Angle | 18″ Plate |

88 Tons | 6″ Angle | 18″ Plate | New, Dual Cylinder, High-Speed, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$35,995.00 | In Stock! |

Get a Quote |

|

Sunrise IW-88SD – Hydraulic Ironworker Capacity: 88 Tons | 6″ Angle | 18″ Plate |

88 Tons | 6″ Angle | 18″ Plate | New, Dual Cylinder, High-Speed, Deep-Throat, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$42,000.00 | In Stock! |

Get a Quote |

|

Sunrise IW-110S – Hydraulic Ironworker Capacity: 110 Tons | 6″ Angle | 24″ Plate |

110 Tons | 6″ Angle | 24″ Plate | New, Dual Cylinder, High-Speed, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$41,995.00 | In Stock! |

Get a Quote |

|

Sunrise IW-110SD – Hydraulic Ironworker Capacity: 110 Tons | 6″ Angle | 24″ Plate |

110 Tons | 6″ Angle | 24″ Plate | New, Dual Cylinder, High-Speed, Deep-Throat, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$47,250.00 | In Stock! |

Get a Quote |

|

Sunrise IW-110SD – Hydraulic Ironworker – W/ Hydraulic Hold Downs Capacity: 110 Tons | 6″ Angle | 24″ Plate |

110 Tons | 6″ Angle | 24″ Plate | New, Dual Cylinder, High-Speed, Optional Hydraulic Plate and Angle Shear Hold Down’s Pre-Installed, Deep-Throat, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$57,250.00 | In Stock! |

Get a Quote |

|

Sunrise IW-135S – Hydraulic Ironworker Capacity: 135 Tons | 6″ Angle | 24″ Plate |

135 Tons | 6″ Angle | 24″ Plate | New, Dual Cylinder, High-Speed, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$51,500.00 | On Order |

Get a Quote |

|

Sunrise IW-135SD – Hydraulic Ironworker Capacity: 135 Tons | 6″ Angle | 24″ Plate |

135 Tons | 6″ Angle | 24″ Plate | New, Dual Cylinder, High-Speed, Deep-Throat, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$57,250.00 | In Stock! |

Get a Quote |

|

Sunrise IW-185SD – Hydraulic Ironworker – W/ Hydraulic Plate and Angle Shear Hold Downs Capacity: 185 Tons | 8″ Angle | 30″ Plate |

185 Tons | 8″ Angle | 30″ Plate | New, Dual Cylinder, Optional Hydraulic Plate and Angle Shear Hold Down’s Pre-Installed, High-Speed, Deep-Throat, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$86,995.00 | On Order |

Get a Quote |

|

Sunrise IW-185SD – Hydraulic Ironworker – W/ Hydraulic Plate Shear Hold Down Capacity: 185 Tons | 8″ Angle | 30″ Plate | Optional Hydraulic Plate Shear Hold Down |

185 Tons | 8″ Angle | 30″ Plate | Optional Hydraulic Plate Shear Hold Down | New, Dual Cylinder, Optional Hydraulic Plate Shear Pre-Installed, High-Speed, Deep-Throat, Includes Efficiency Package, 2″ Oversize Die-Block, New 3 Year Warranty! |

$84,995.00 | In Stock! |

Get a Quote |

|

Sunrise IW-95KD – Hydraulic Ironworker Capacity: 95 Tons | 5″ Angle | 16″ Plate |

95 Tons | 5″ Angle | 16″ Plate | New, Dual Cylinder, High-Speed, Includes Efficiency Package, Integrated Hydraulic Hold Downs, 2″ Oversize Die-Block, New 3 Year Warranty! |

$44,750.00 | In Stock! |

Get a Quote |